Introduction to PEEK Carbon Fiber Modified Pipe

The Carbon PEEK Tube, also known as Carbon Fiber Reinforced PEEK Tube or PEEK carbon fiber Tube, is a new - type composite. It is crafted by combining PEEK (polyetheretherketone) resin and carbon fiber through a specialized process. This unique combination fuses the best characteristics of both materials, resulting in a pipe with outstanding properties.

Manufacturing Process

High - quality carbon fibers are carefully selected for Carbon PEEK Tube manufacturing. These fibers are pre - treated to enhance their adhesion to the PEEK resin. The heat - and chemical - resistant PEEK resin is then melted. For the production of Carbon PEEK Tube, the carbon fibers are evenly coated with the resin. The fiber - resin mix is shaped into a tube by filament winding (where strands are wound around a mandrel under controlled tension) or extrusion (pushing through a circular - cross - section die). Heat treatment and surface finishing are carried out to optimize the properties of the PEEK carbon fiber Tube.

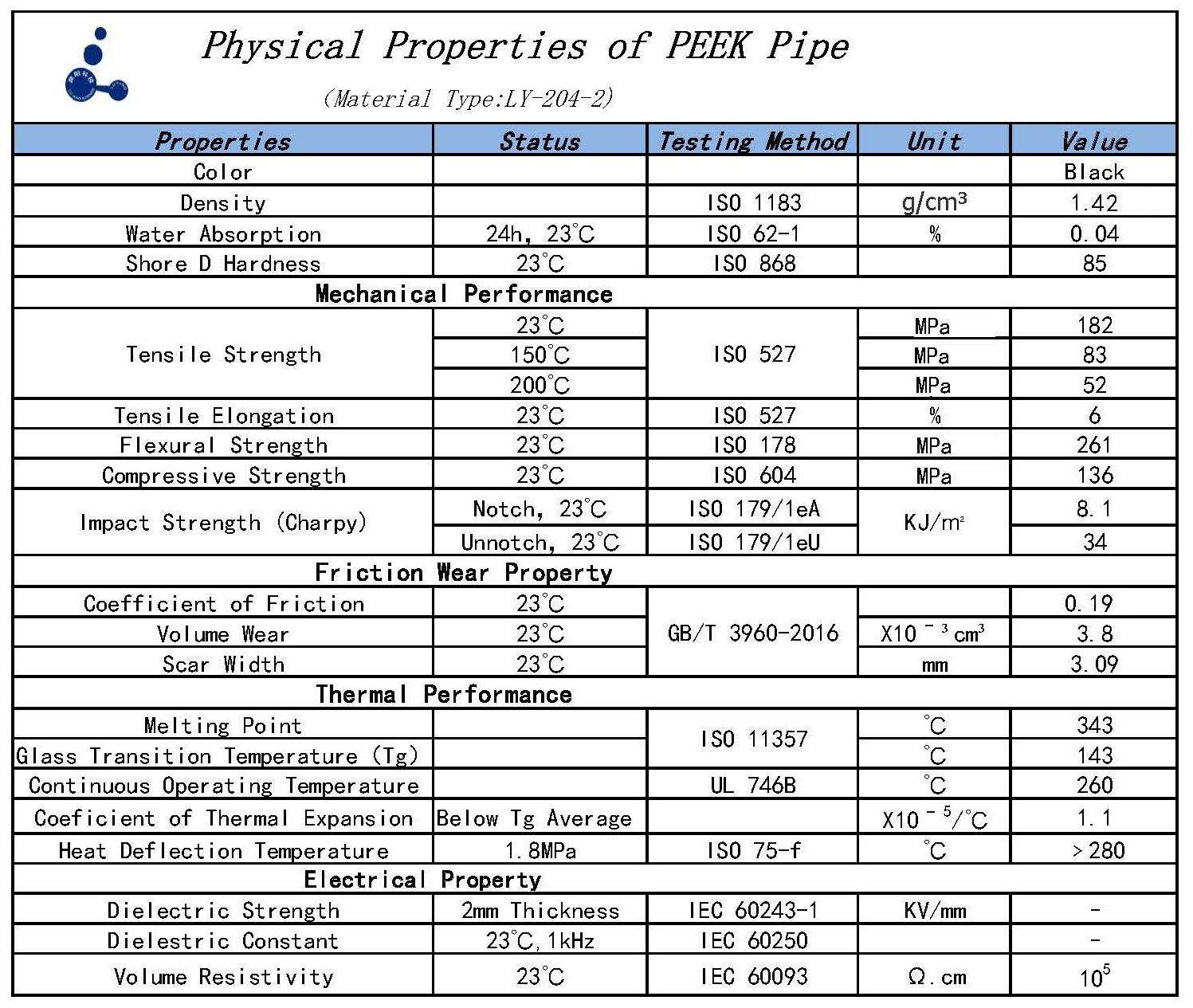

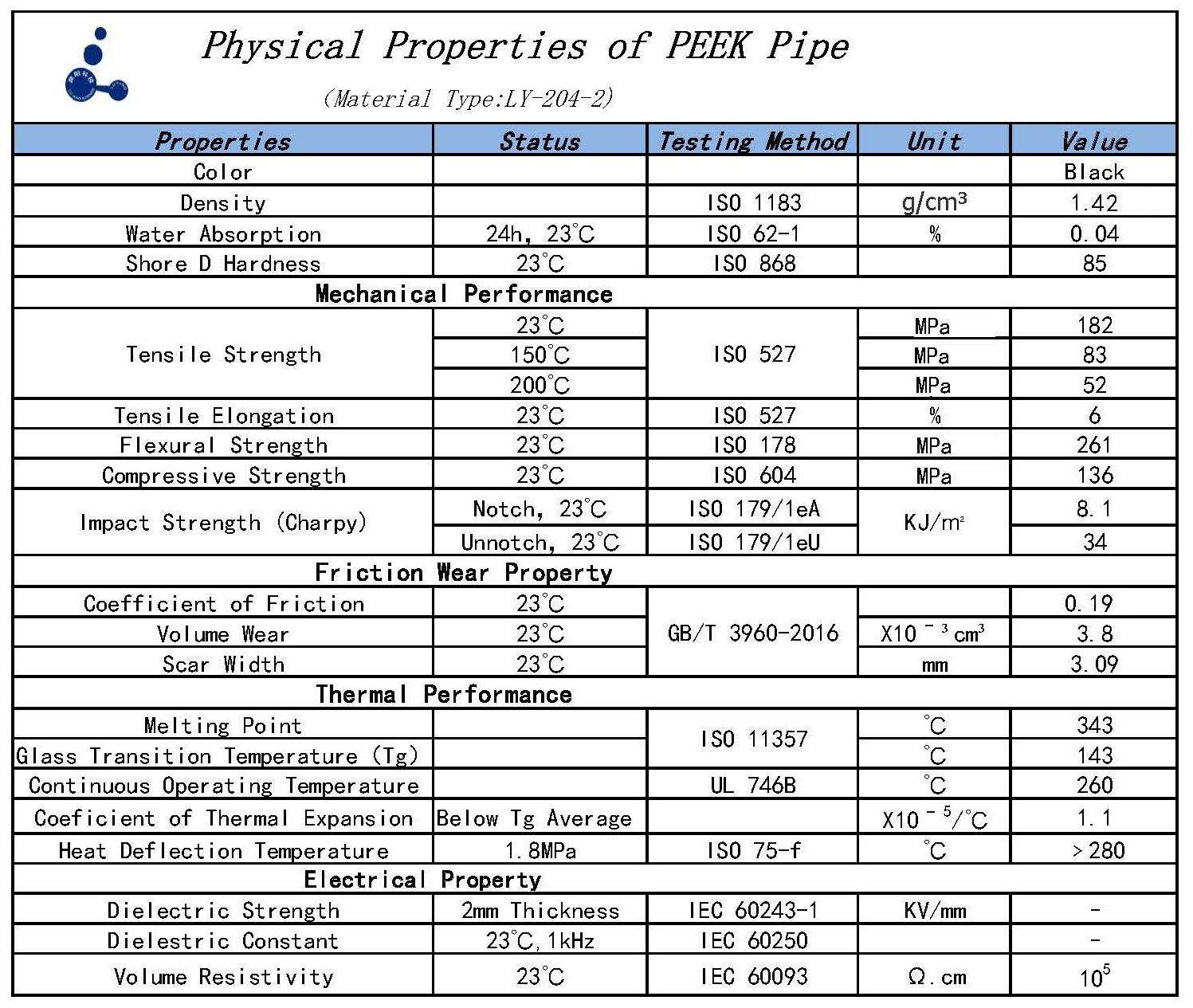

Material Properties

High - Temperature Resistance

PEEK resin has good heat resistance, and when combined with carbon fiber in Carbon PEEK Tube, it can withstand even higher temperatures. The Carbon PEEK Tube can maintain its mechanical and chemical properties up to PEEK's glass transition temperature (about 143°C), and sometimes endure short - term higher heat. This makes it suitable for high - temp settings like oil wells or industrial furnaces where PEEK carbon fiber Tube's heat resistance is crucial.

High Strength - to - Weight Ratio

Carbon fibers significantly boost the strength of Carbon PEEK Tube, allowing it to handle high internal and external pressures. The light weight of both materials gives Carbon Fiber Reinforced PEEK Tube a high strength - to - weight ratio. In aerospace, this property helps reduce aircraft weight while maintaining strength, such as in fuel lines made of PEEK carbon fiber Tube.

Chemical Stability

PEEK resin imparts great chemical resistance to the Carbon PEEK Tube. It can resist strong acids, alkalis, and organic solvents. In chemical and pharmaceutical industries, Carbon Fiber Reinforced PEEK Tube can transport corrosive substances without corroding, ensuring pipeline integrity. The PEEK carbon fiber Tube's chemical stability is vital in these applications.

Good Dimensional Stability

Carbon PEEK Tube, Carbon Fiber Reinforced PEEK Tube, and PEEK carbon fiber Tube all exhibit good dimensional stability. They don't expand or contract much with temperature or pressure changes. This is important for applications needing precise dimensions, like in precision - engineered industrial gear or aerospace parts.

Advantages of PEEK carbon fiber modified pipe:

1. Due to the reinforcement of carbon fiber, Carbon PEEK Tube has the characteristics of high strength and lightweight, which can effectively reduce the weight of the overall structure.

2. Under cyclic loading, Carbon Fiber Reinforced PEEK Tube exhibits good fatigue resistance, extending the service life of the tube.

3. Carbon Fiber Reinforced PEEK Tube can be recycled and reused, in line with modern green and environmentally friendly production concepts.

Details of Carbon Fiber Reinforced PEEK Tube:

Applications of Carbon Fiber Reinforced PEEK Tube:

Petrochemical industry, aerospace, automobile industry, medical equipment, sports equipment, etc.

In the petrochemical industry, PEEK carbon fiber Tube is used to manufacture pipeline systems, such as oil transportation pipelines, chemical reactor pipelines, etc. In the aerospace field, PEEK carbon fiber Tube is used in the manufacturing of pipelines in key parts such as aircraft hydraulic systems and fuel systems.

Why choose us?

Our team consists of a group of experienced materials scientists, engineers and technicians to provide you with a full range of technical support and solutions.

According to your specific needs, we can provide customized PEEK carbon fiber Tube specifications and sizes to meet your individual needs.